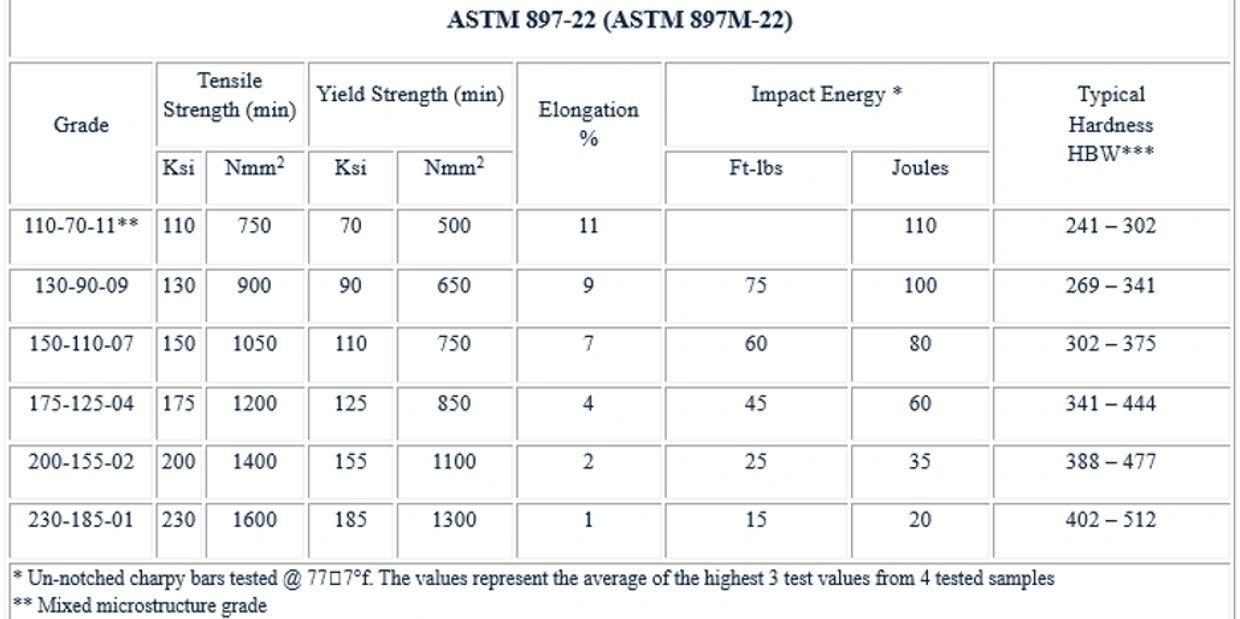

Austempering is a thermal process applied to ferrous materials that imparts superior mechanical properties over conventionally treated parts at a given hardness level. This process was employed early on with steel fasteners – clips and clamps, that were dimensionally critical for the automotive and appliance industries. As the technology was better understood, many other applications were discovered which benefitted from Austempering.

Material requirements for steel include a minimum of .40% Carbon (some alloy steels may require slightly less Carbon). A section size (thickness) that can be fully quenched (up to several inches for some alloys). A hardness range (strength level) that can be achieved by quenching above the Martensite start line, as high as HRC 55.

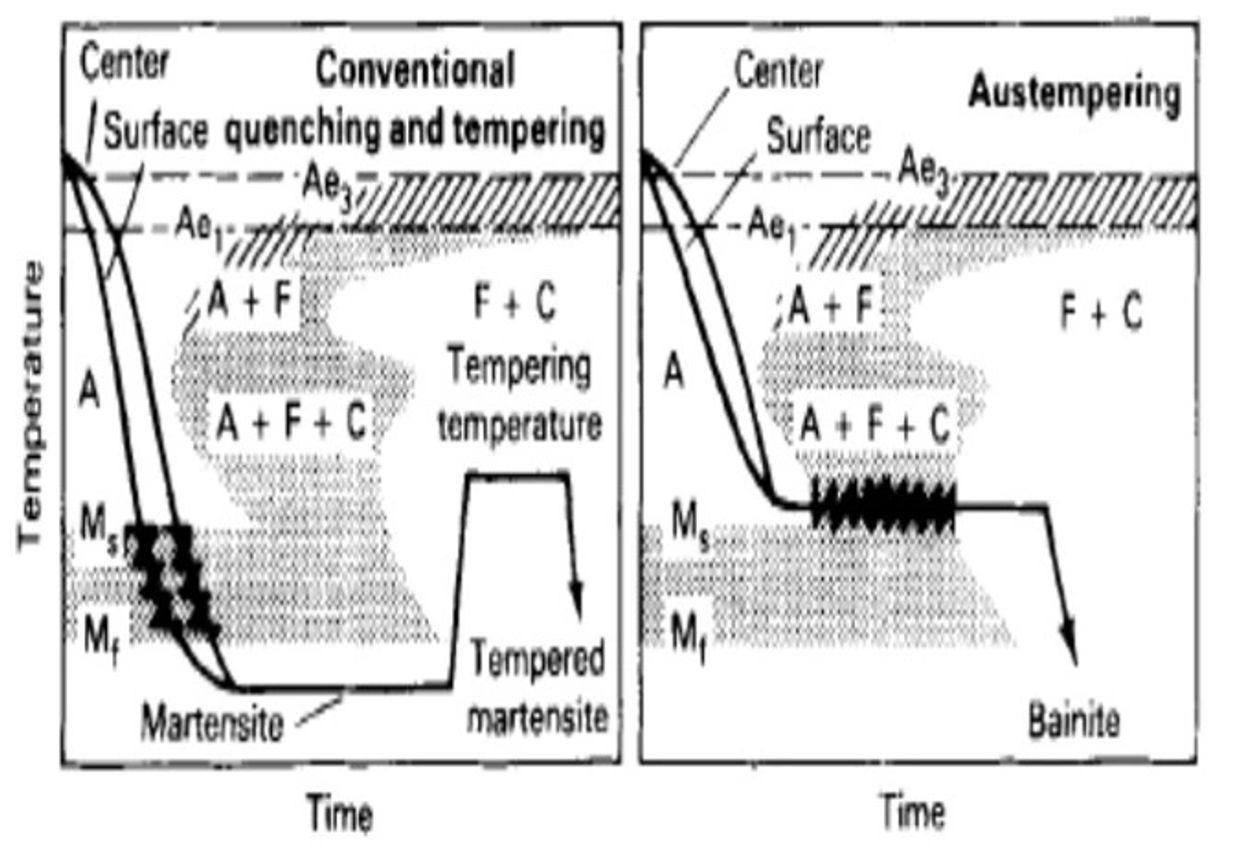

Austempering achieves its unique properties due to the elevated quench temperature process step. Quenching to an elevated temperature and holding for a time sufficient to complete the microstructural transformation to bainite produces desired mechanical properties and reduces distortion significantly.