In the fields of agriculture and construction, ADI is essential for components like sprockets, steering knuckles, and mower blades. Its durability ensures reliable performance in ground engaging hardware such as shanks, rippers, and bucket teeth, as well as in structural parts like till points and lifting arms.

The automotive industry benefits from ADI in critical components such as CV joints, gears, and suspension members. ADI’s toughness and fatigue resistance make it ideal for engine mounts, control arms, and camshafts, helping to improve safety and performance in vehicles.

For the defense sector, ADI is crucial for manufacturing robust track links, armor, and hardware for trucks and armored vehicles. Its excellent strength-to-weight ratio ensures that essential military equipment meets the highest standards of durability and reliability.

ADI is extensively used in the heavy truck industry for manufacturing suspension brackets, housings, and pintle hooks. Its capacity to withstand heavy loads makes it perfect for critical truck components like cross members, hubs, and timing gears.

ADI's versatility extends to miscellaneous applications such as housings, shredders, and components for trolleys, conveyors, and cranes. It is also used in wear plates and wheel hubs, where its wear resistance and toughness are invaluable.

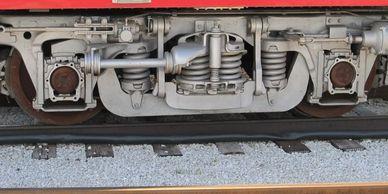

In rail applications, ADI proves essential for suspension housings, wheels, and track plates. Its ability to absorb shock and resist wear supports the safety and longevity of railcar components like friction wedges and nipper hooks.

The sporting goods industry utilizes ADI for manufacturing high-performance items like bobsleigh runners, sword blades, and various gun components, where its impact resistance and durability enhance the competitiveness and safety of sporting equipment.